Deburring

If sheet metal is produced using a laser cutting process, burrs and slag are created on the laser entry and exit side due to thermal influences.

Burrs are also created by material displacement during the mechanical processing of milled and turned parts as well as during punching or sawing.

An overview of our service portfolio:

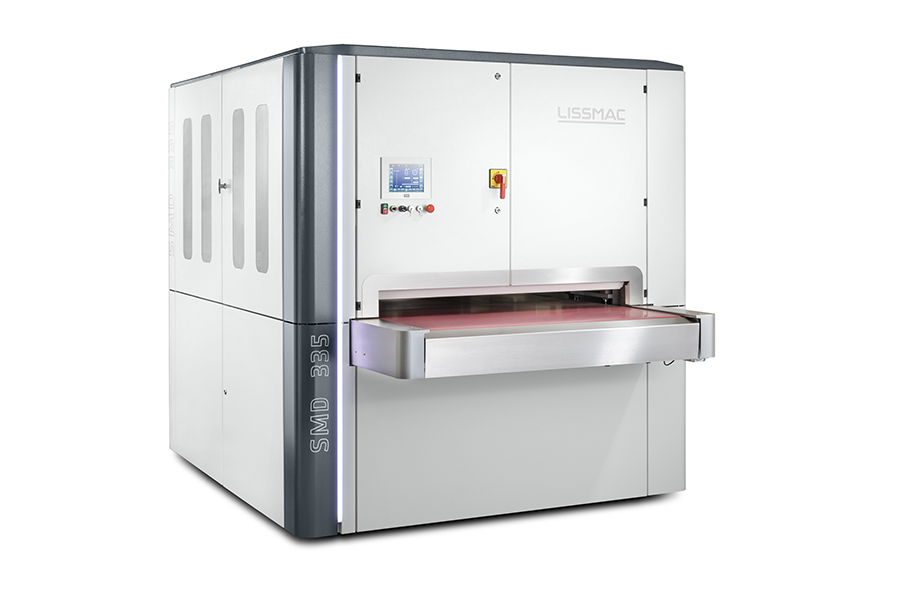

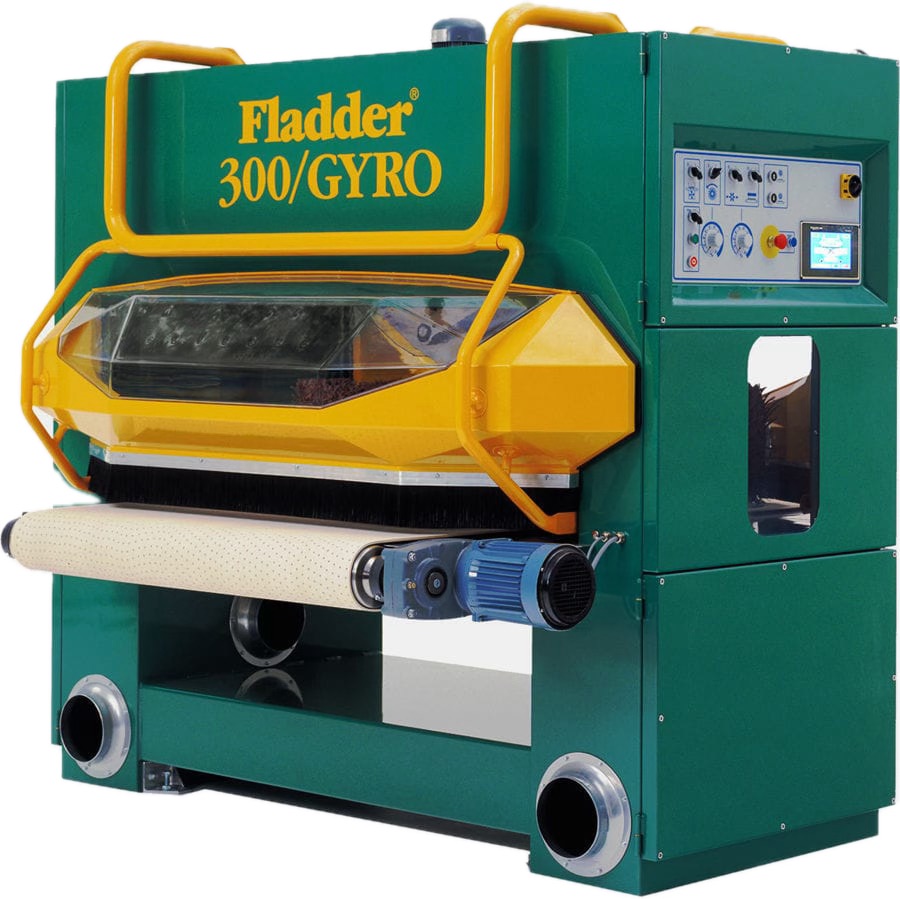

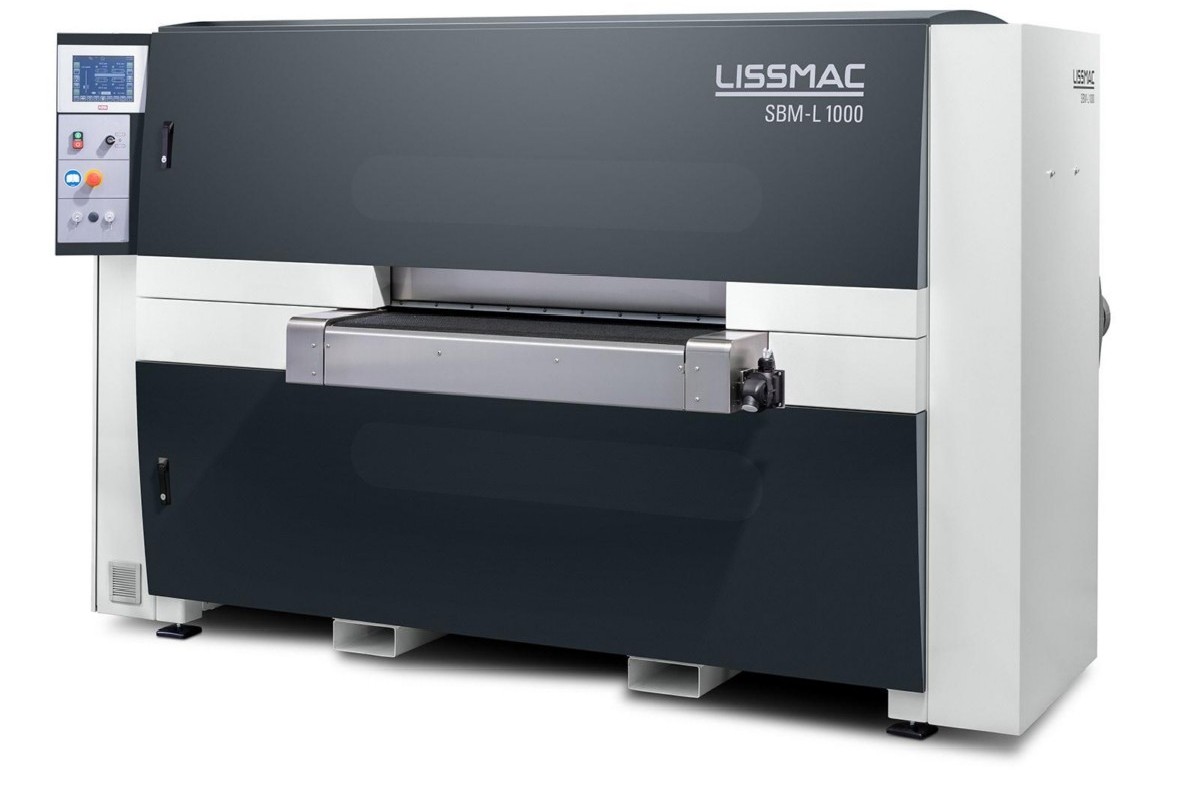

- Wet and dry sanding: Use of sanding machines with deburring rollers, abrasive cloths and deburring brushes in various grit sizes for processing sheet metal parts with a maximum width of 1,600 mm and a sheet thickness of up to 20 mm

- Edge breaking: Use of dry grinding machines with lamellar rollers in various grit sizes and corundums

- Vibratory finishing process: Efficient sanding using vibratory finishing technology

- Manual sanding: Hand-held sanding machines such as angle grinders and air sanders

- Customisable abrasives: Use of sanding belts and abrasives in different grit sizes, individually adapted to specific requirements